What Makes Robotic Cable Assemblies Unique? Specs, Performance & Design Considerations

- Jeff Bowman

- Nov 19, 2025

- 3 min read

Updated: Dec 1, 2025

Understanding the Unique Requirements of Robotic Cable Assemblies

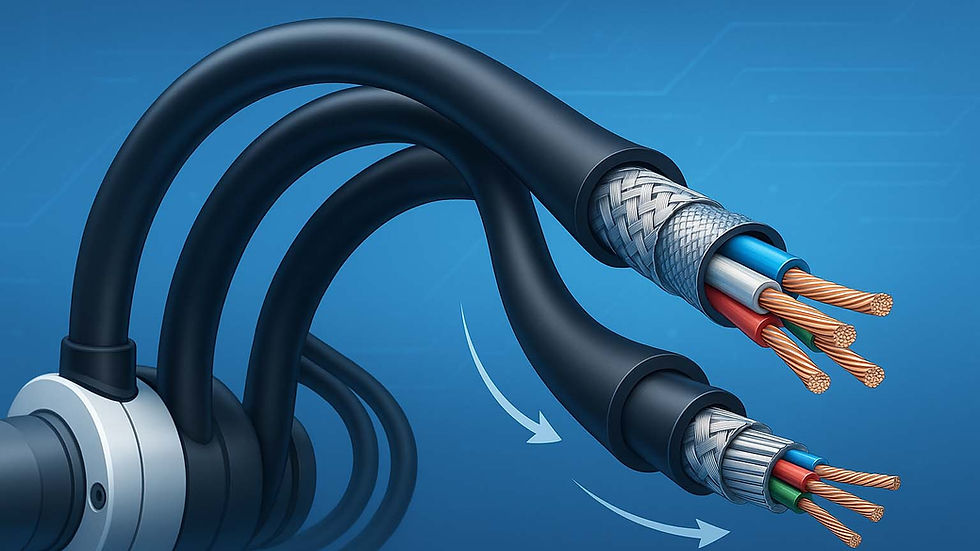

As automation expands across factories and distribution centers, robotic cable assemblies have become essential for keeping motion systems running smoothly. These cables aren’t like everyday wiring. They’re engineered specifically for continuous motion, harsh environments, and long-term signal reliability.

A robotic cable may flex or twist millions of times throughout its lifespan. If the cable fails, the robot fails. That’s why high-performance robotic cable assemblies must be designed with the right materials, shielding, and mechanical structure from the start.

What Sets Robotic Cables Apart

1. Flex Life and Torsional Durability

Robotic cables are purposely built for motion—often nonstop.

Rated for 10+ million flex cycles.

Designed to twist up to ±360°/m in multi-axis robot arms.

Structured to prevent corkscrewing and conductor fatigue.

This level of durability is essential for industrial robots, cobots, pick-and-place systems, and automated assembly lines.

2. Specialized Jacket and Reinforcement Materials

Materials determine how well a cable holds up under stress.

PUR or TPE jackets resist oils, chemicals, and abrasion.

Fine-stranded copper improves flexibility.

Kevlar® or aramid yarns prevent kinks and internal damage.

3. Advanced Shielding for EMI/RFI Protection

Robotic equipment requires clean and consistent data flow.

Uses foil + braided copper shielding.

Maintains shielding integrity even under constant motion.

Supports servo feedback, sensors, vision systems, and communication lines.

Good shielding prevents electrical noise from disrupting automation performance—especially in PLC-heavy production environments.

4. Hybrid Cable Configurations

Many robotic systems rely on hybrid cables to simplify routing.

Power, signal, communication lines, and pneumatic tubes combined in one assembly.

Reduces weight and clutter in drag chains.

Requires precise internal layer design to avoid EMI issues.

Hybrid robotic cables improve reliability and reduce installation complexity.

5. Thermal, Flame, and Regulatory Ratings

Robotic cable assemblies often operate in demanding environments.

Temperature ratings from –40°C to +90°C (higher for weld cells).

Flame ratings like UL VW-1 and CSA FT1/FT2.

Compliance with UL AWM, VDE, CE, or other global standards.

These ratings ensure cables stay safe and functional even in harsh industrial settings.

6. Bend Radius and Drag Chain Compatibility

Tight routing is common in robotic systems—and cables must be designed accordingly.

Bend radii as tight as 5× outer diameter.

Optimized for drag chains and robotic cable carriers.

Strain reliefs, overmolds, and potting protect connectors.

Why These Specs Matter

When robotic cables are poorly designed, problems appear quickly:

Data loss or intermittent signals.

Cracked jackets, insulation damage, or conductor failure.

Production downtime and maintenance costs.

Shortened robot lifespan due to cable wear.

In robotics, cable reliability equals system reliability. Even the most advanced robot can’t perform effectively if its cables fail.

Sanbor Manufacturing: Building for Robotic Motion

Sanbor Manufacturing specializes in high-reliability robotic cable assemblies engineered for motion, durability, signal integrity, and long service life.

Our Southeast Asian factories in Indonesia and Malaysia support:

Hybrid robotic cable assemblies with overmolded connectors and strain relief.

High-mix, mid-volume production ideal for robotic OEMs and automation integrators.

Open-book costing and transparent supply chain management.

Flexible fulfillment for U.S. and global customers.

Whether your project calls for a drag-chain-rated multi-core cable or a complex hybrid robotic assembly with twisted pairs, power conductors, and pneumatic tubing, our engineering and manufacturing teams can build it to your exact specifications. Take a look at some of the most frequently asked questions we hear.

Want to Learn More?

Explore how Sanbor Manufacturing can support your robotic cable assembly needs—from early design input to full production.

Visit www.sanbormfg.com or contact our team directly to get started. Phone: 610-530-8500 or email sales@sanbormfg.com.

The Future of Robotic Cable Assemblies

As technology advances, the demand for more sophisticated robotic cable assemblies will continue to grow. We must adapt to these changes to remain competitive.

Innovations in Materials

The future of robotic cables lies in innovative materials. New compounds can enhance flexibility and durability. This means longer-lasting cables that can withstand even harsher conditions.

Integration with Smart Technologies

As robotics become smarter, so too must the cables that connect them. Future robotic cable assemblies may integrate sensors that monitor performance in real-time. This will allow for predictive maintenance and reduce downtime.

Sustainability Considerations

Sustainability is becoming increasingly important. Manufacturers are looking for ways to produce cables that are not only effective but also environmentally friendly. This could involve using recyclable materials or reducing waste during production.

Conclusion

In conclusion, understanding the unique requirements of robotic cable assemblies is crucial for ensuring the reliability and efficiency of robotic systems. At Sanbor Manufacturing, we are committed to staying ahead of the curve. Our focus on innovation, quality, and customer satisfaction positions us as a trusted partner for your robotic cable assembly needs.

Let’s work together to build resilient and cost-effective supply chains that can adapt to the ever-changing landscape of automation.