Precision in the Skies: Custom Aerospace Cable Assemblies & Wire Harnesses

- Sean Campbell

- Nov 12, 2025

- 3 min read

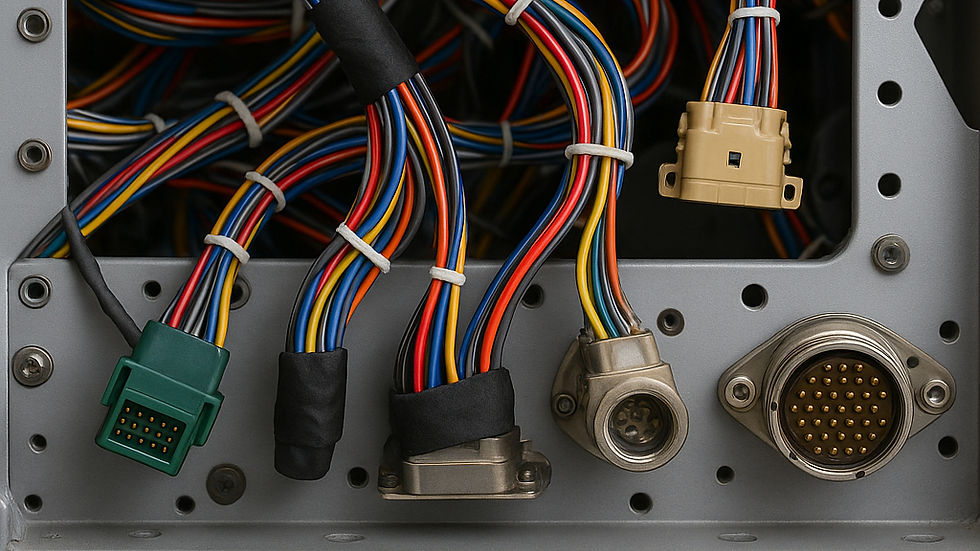

The aerospace industry demands perfection. Every component must function flawlessly in the most extreme environments. Among the most critical components are wire harnesses and cable assemblies, which serve as the nervous system of aircraft and spacecraft, transmitting power, data, and signals reliably under extraordinary conditions. Sanbor Manufacturing produces aerospace cable assemblies and wire harnesses that meet the industry’s strictest quality, safety, and performance standards.

What Makes Aerospace Cable Assemblies and Wire Harnesses Unique?

Aerospace cable assemblies are rugged and engineered for mission-critical reliability and weight optimization. Below are key design features that distinguish them from standard industrial harnesses.

Extreme Temperature Resistance

Aerospace systems experience vast temperature swings, from -65°C to +200°C. To ensure stable operation, Sanbor uses high-performance insulations such as PTFE, FEP, Kapton®, and Teflon®—materials known for exceptional thermal endurance.

Lightweight Construction

In aerospace design, every gram counts. Sanbor’s harnesses use lightweight conductors (tinned copper, aluminum) and low-mass insulation materials to minimize weight without sacrificing performance. Shielding is carefully optimized to provide EMI protection while keeping total mass low.

Vibration and Shock Tolerance

Aircraft and spacecraft endure extreme vibration and shock forces, especially around propulsion and avionics systems. Our cables are built to handle 50–200 g-force loads, using robust strain reliefs, secure bundling, and Kapton® lacing techniques to maintain connection integrity.

EMI/RFI Shielding

Clean, reliable communication is essential for flight safety. Sanbor integrates braided, foil, or composite shielding to eliminate electromagnetic (EMI) and radio-frequency interference (RFI), ensuring uninterrupted signal transmission.

Multi-Core Signal Integration

To conserve space and simplify installations, Sanbor engineers multi-core assemblies that integrate power, signal, coaxial, and data lines into a single, efficient harness. These designs maintain tight bend radii, minimal crosstalk, and superior signal performance.

Built to Aerospace Standards

Sanbor Manufacturing adheres to globally recognized aerospace and defense standards, including:

AS9100 – Aerospace quality management system

MIL-STD-810 – Environmental engineering and testing protocols

IPC/WHMA-A-620 – Acceptability for cable and wire harness assemblies

RTCA/DO-160 – Environmental testing for airborne equipment

These certifications ensure that every Sanbor aerospace assembly meets or exceeds the quality and reliability expectations of leading OEMs worldwide.

Applications Across Aerospace Systems

Sanbor’s wire harnesses and cable assemblies are engineered for a broad range of aerospace platforms, including:

Avionics (cockpit displays, flight control systems)

Satellite communications

Unmanned Aerial Vehicles (UAVs)

Engine Control Modules (ECMs)

Landing gear and sensor systems

Cabin lighting and power systems

Materials and Testing Protocols

Sanbor sources aerospace-grade materials to ensure optimal performance and durability:

Silver- or nickel-plated copper conductors

Fluoropolymer insulation (PTFE, ETFE, FEP)

MIL-SPEC and FAA-approved connectors (D-Sub, MIL-C-38999, circular, coaxial)

Every assembly undergoes rigorous validation, including:

Hi-pot testing for insulation integrity

Continuity and resistance verification

Thermal cycling for extreme temperature performance

Vibration and shock simulation

Salt fog and humidity exposure for corrosion resistance

How Sanbor Manufacturing Supports Aerospace OEMs

Sanbor Manufacturing combines U.S.-based engineering expertise with cost-efficient, AS9100-certified production across Southeast Asia to provide flexible, high-quality aerospace manufacturing solutions.

Engineering and design support from our U.S. team

Scalable production—from prototype to full production volumes

Manufacturing in Indonesia and Malaysia for cost-optimized, aerospace-certified production

Dedicated U.S.-based project management and quality oversight

Our global footprint enables precision manufacturing, supply chain flexibility, and all-in price certainty—helping aerospace OEMs maintain performance, reliability, and profitability even in a dynamic global market. Our Indonesia-based aerospace-certified facility ensures we meet the strictest global requirements while delivering cost-effective, reliable solutions.

Partner with Sanbor Manufacturing

Precision and reliability are non-negotiable. Sanbor Manufacturing delivers custom wire harnesses and cable assemblies for the aerospace industry that perform under pressure and are engineered to meet the demands of flight. Tested to endure extremes and certified to the highest aerospace standards, Sanbor delivers each and every time.

For more information, contact us at 610-530-8500 or email sales@sanbormfg.com.