- Jeff Bowman

- Dec 4, 2025

- 11 min read

Building Cable Assemblies for Tight Spaces: Routing, Bend Radius & Strain Relief Strategies

Best Practices for Cable Assemblies in Tight Spaces

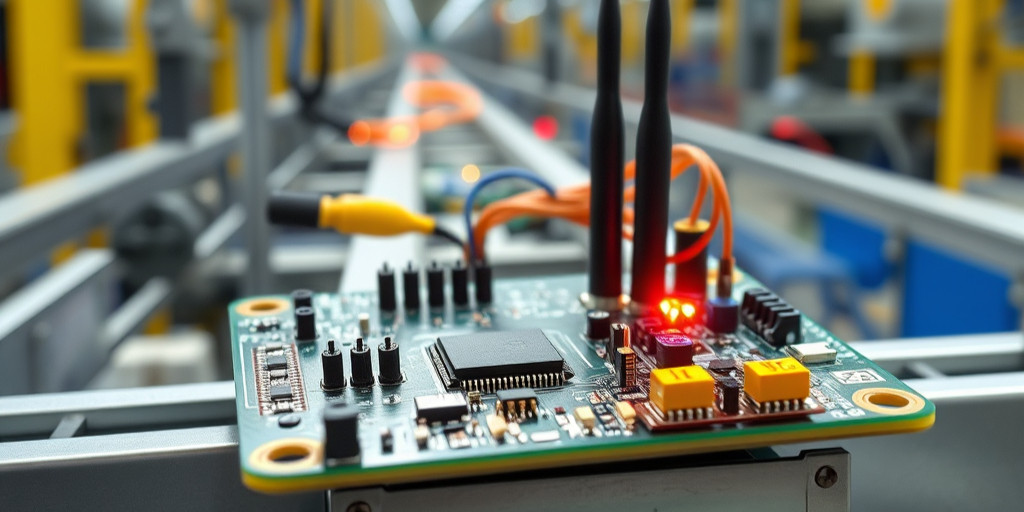

As devices shrink and electronics become increasingly compact, OEMs face greater challenges when designing cable assemblies that fit and perform reliably within tight spaces. Limited routing room, sharp enclosure angles, and dense internal components all create mechanical stress that can reduce cable life, cause intermittent failures, or complicate downstream assembly.

This article explores how proper bend-radius management, routing strategies, and strain-relief design help OEMs build compact, durable cable assemblies engineered for long-term performance.

Why Tight-Space Cable Engineering Matters

Modern industrial, medical, aerospace, automotive, and especially electronic systems often require more functionality in less space. That means cables must perform under:

-

Restricted enclosure geometries

-

Tight bend paths

-

Vibration and movement

-

Temperature fluctuations

-

EMI-sensitive environments

Poor routing or inadequate mechanical support can lead to:

-

Jacket cracking

-

Conductor fatigue

-

Signal loss or interference

-

Premature field failures

Designing for tight spaces is not just about packaging. it's ensuring lifecycle reliability.

Understanding Minimum Bend Radius

Every cable has a required minimum bend radius, determined by conductor stranding, shielding, insulation, and jacket material. Exceeding this radius can deform the cable, damage internal conductors, and reduce flex life.

Best Practices for Preserving Bend Radius

-

Choose fine-stranded conductors for increased flexibility

-

Use ultra-flexible jacket materials like PUR, TPE, or silicone

-

Integrate right-angle or low-profile connectors to avoid harsh bends

-

Pre-form cable shapes to match the enclosure’s geometry

-

Add flexible strain-relief boots to reduce concentrated stress

Maintaining proper bend radius dramatically improves durability in compact assemblies.

Effective Routing Strategies for Tight Enclosures

Thoughtful routing is critical for cable integrity, serviceability, and manufacturability.

Optimal routing techniques include:

-

Replace sharp 90° turns with smooth, sweeping curves

-

Maintain separation between high-power and low-signal cables

-

Avoid pinch points against housing edges or hardware

-

Use proper cable-bundle support without over-tightening ties

-

Employ 3D routing during design to visualize path constraints

Labeling each branch, segment, and connection point also improves long-term maintainability and reduces assembly errors.

Strain Relief: Essential for Tight-Space Reliability

Strain relief protects terminations from mechanical pull, flex, and vibration — especially when cables are installed in confined or high-motion applications.

Common strain-relief options for compact assemblies:

-

Overmolded strain relief for custom, low-profile geometries

-

Heat-shrink boots for tight, adjustable reinforcement

-

Connectors with built-in strain relief for micro-sized assemblies

-

Grommets or bushings where cables exit enclosures

Well-designed strain relief extends product life and reduces warranty claims.

How Sanbor Manufacturing Supports Tight-Space Cable Assembly Design

With extensive experience across multiple industries and electronics environments, Sanbor Manufacturing helps OEMs optimize compact cable designs through:

-

Early-stage design for manufacturability (DFM) reviews

-

Custom overmolding and right-angle connector solutions

-

Precision routing and bundling for high-density applications

-

Multi-regional production to deliver predictable, stable costs

OEMs can explore Sanbor Manufacturing’s cable assembly contract manufacturing services to support projects requiring advanced routing and compact footprints.